Product Details

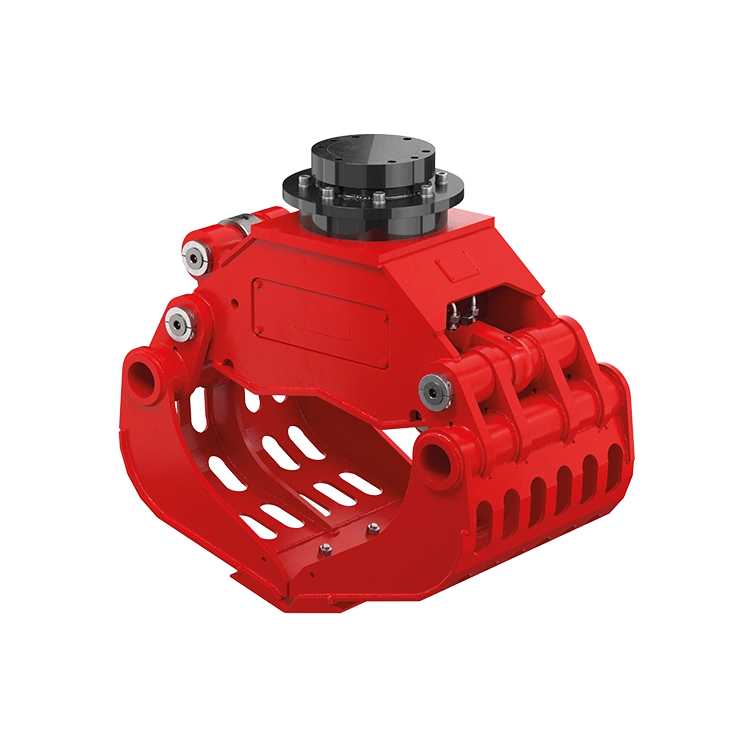

HARDOX® 450 – for necessary wear resistance

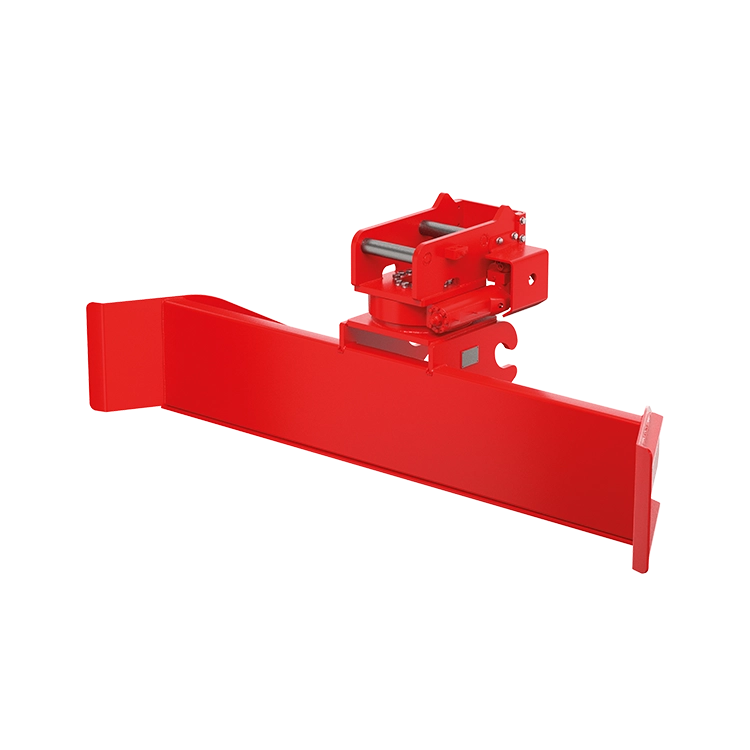

Torsion box with optimally integrated mounting in the bucket and maximum torsional rigidity, with minimum weight

Extended cutting edges – for easy continuation of the trench contour

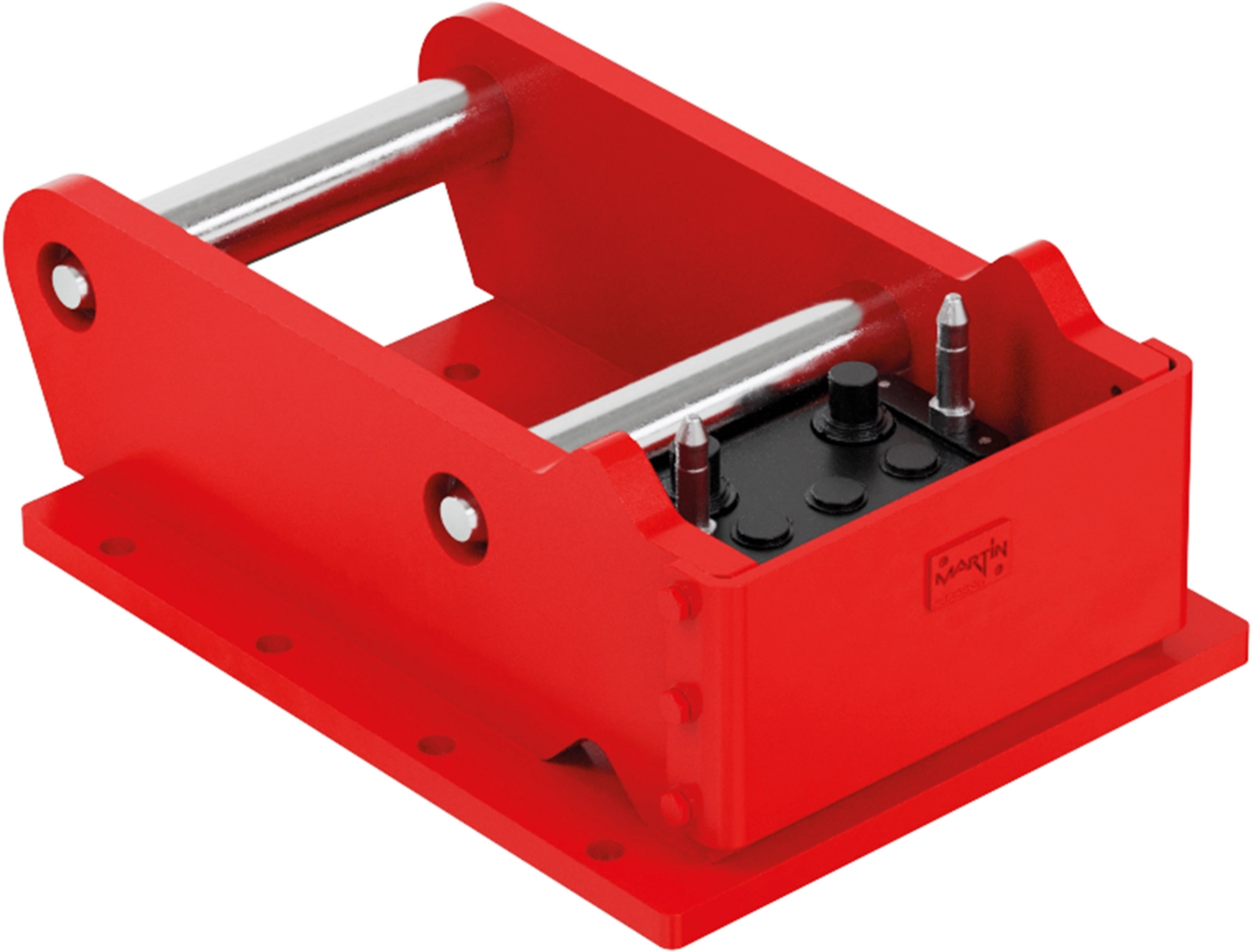

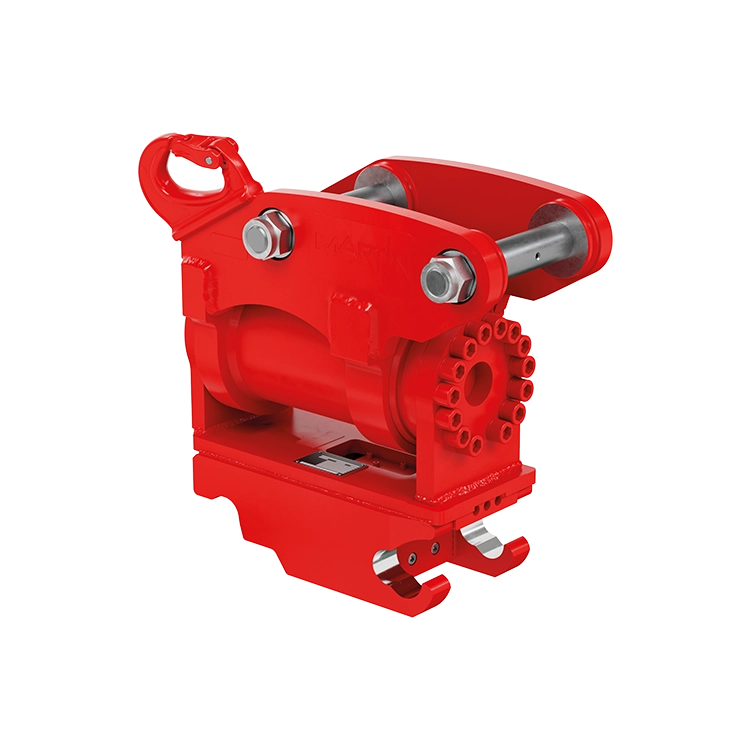

Hard chrome-plated pins with full connection for precise and wear-resistant mounting

Conical shape – for easier emptying

The TRB is a part of the Dedicated System